A very common question I get from viewers and users of my Brewing Recipe Spreadsheet is:

“Why do the outputs (Efficiency, O.G., F.G., ABV, etc) of your recipe calculator spreadsheet differ from <fill in the blank> recipe calculator?”

I’ve answered this question so many times that I decided to write this article so that I can simply point back to it whenever I am asked the question going forward. Here it goes:

There are a number of reasons for varying outputs between different brewing calculators.

Let’s go over some of them.

They Are Only Estimates

All recipe calculators are only estimating outputs based on various assumptions; not reality.

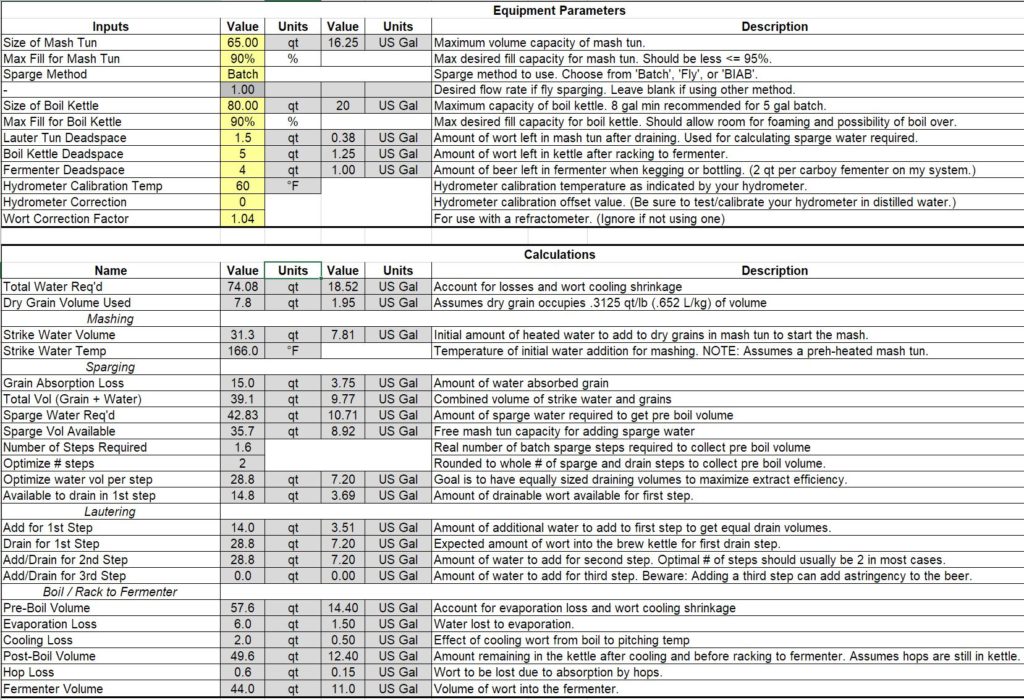

Each one has its own assumptions built in about things like PPG (points per gallon) values of various grains, losses along the way, what constitutes a “batch size” (e.g. into the fermenter or the final packaged quantity), and what type of “efficiency” (there are a number of them) they are using.

None give you real numbers; only approximations based upon assumptions. How close your actual measured values align with your as-designed recipe is dependent on the correctness of your assumptions, the accuracy of your inputs, the abilities of the chosen recipe calculator, your brew system and process, and your skills.

Different Assumed PPG (Points Per Gallon) Values

All other recipe calculators I’ve EVER seen or used (outside my own), use a generic grain list with generic values for Malt PPG values that do not provide you with accurate outputs.

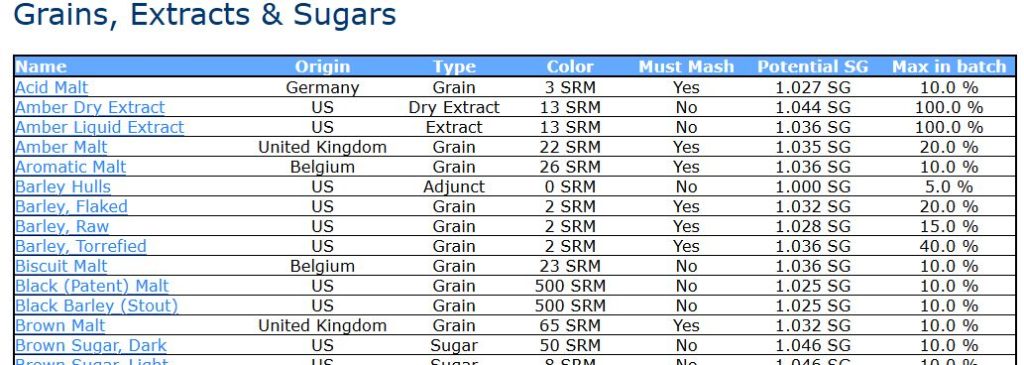

BeerSmith has an example of a generic list on their web site:

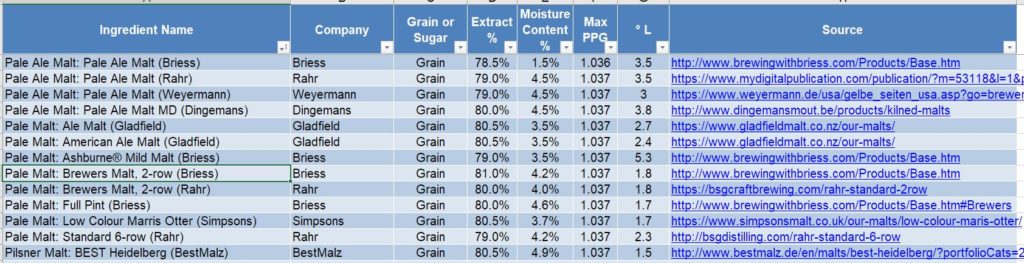

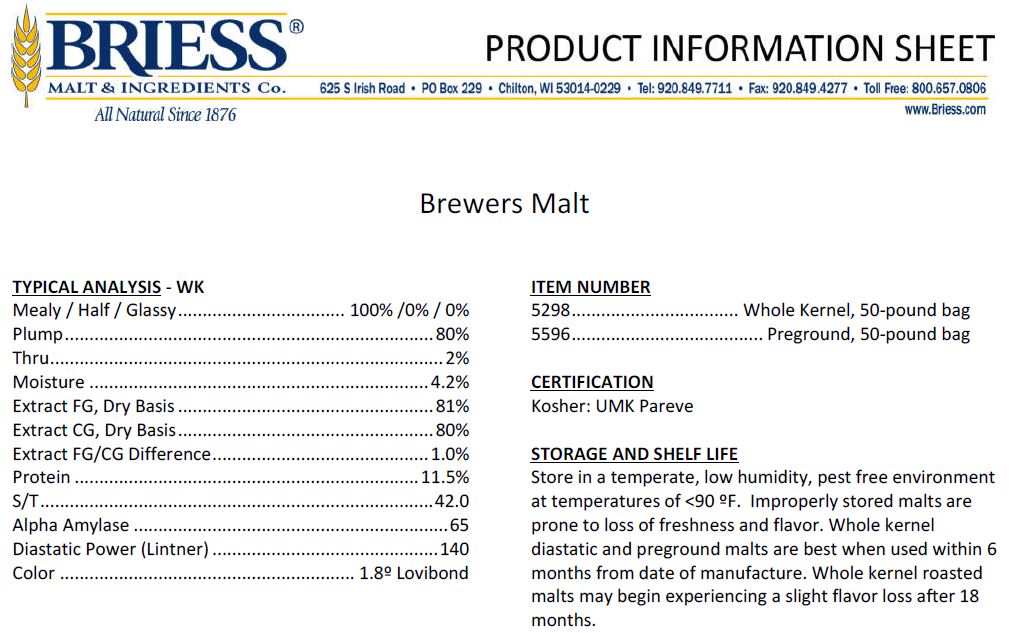

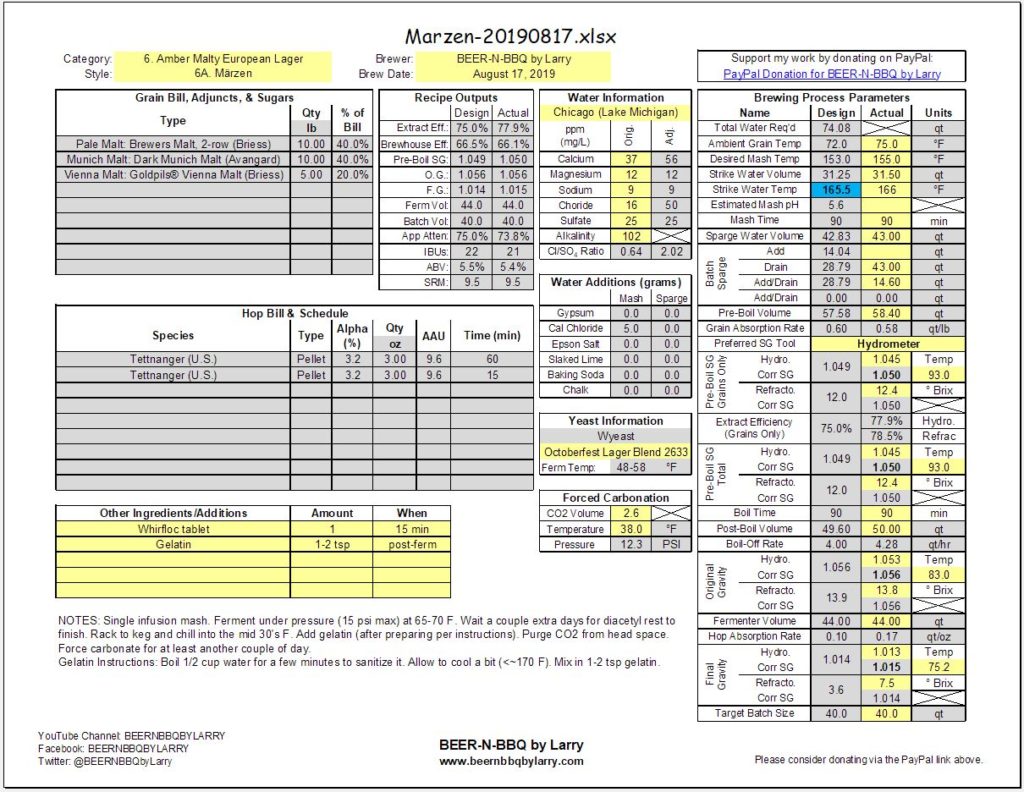

However, my spreadsheet uses actual Maltster datasheets to determine the PPG values of almost every producer and brand of grain making my values the most realistic and accurate.

Different Definitions of “Batch Size”

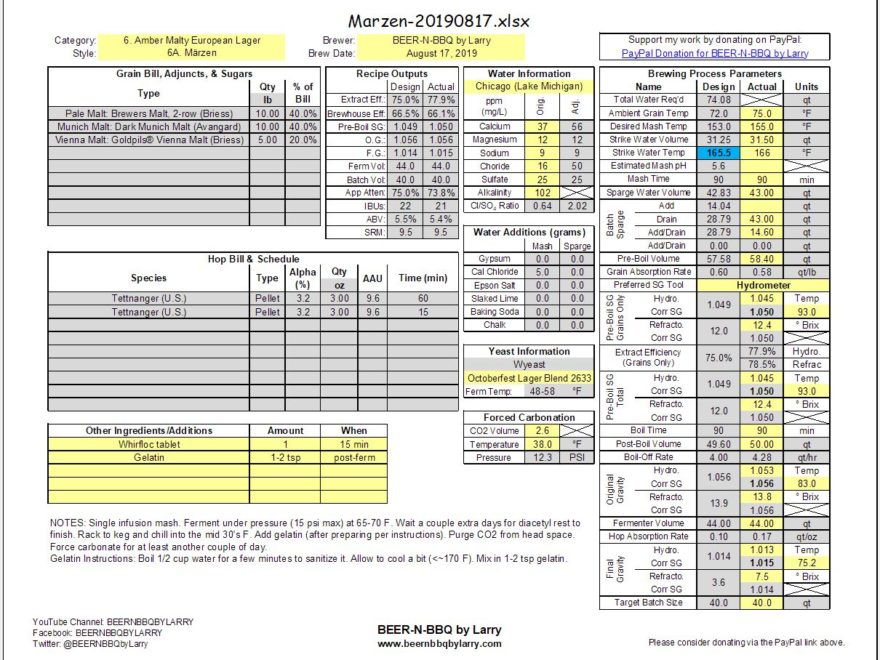

Every recipe calculator has its own definition of what constitutes a “batch size”. For most of them, it is for the volume into the fermenter. Some use volume left in kettle after boil.

My spreadsheet uses the final packaged beer volume (which is what just about everyone is trying to get to anyway, right?). It works backward from the final packaged volume size adding in expected losses along the way to come up with a starting volume of water for your brew day. (This is the better way to design good reproducible recipes IMHO.)

Since outputs like OG (Original Gravity) and ABV (Alcohol By Volume) are affected by the amount of water (and grain. See earlier section), you need to understand and know that each brewing tool assumes a different quantity of final water (and sugars. See earlier section).

Different Definitions of “Efficiency”

There are many types of “efficiencies” used in brewing. The two most common are: Extract (Mash) Efficiency and Brewhouse Efficiency.

Most brewing software (outside mine) unfortunately uses “Brewhouse Efficiency” (which is a useless number for home brewers in IMO) to calculate (estimate really. See above.) final extracted sugar and volume of the wort into the fermenter.

This is a single composite number that takes into account mash efficiency (see below) and all mashing, lautering, and kettle losses along the way and is only useful for repeated brews on the same brew system. That is the problem with it!

All of those important values are buried and hidden away making it difficult for that beer to be brewed the same exact way on another system since each system has its own extract efficiency and losses.

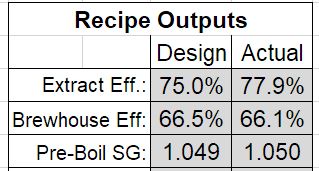

My spreadsheet use the more appropriate “extract efficiency“. Using extract efficiency allows you to scale recipes or adjust them for another brew system to ensure that your OG, ABV, and other outputs are consistent from batch to batch and brewing system to brewing system. The individual (and measurable) losses are added in a separate area (Brewhouse Setup tab). By separating brewhouse efficiency back into its individual components of extract efficiency and actual losses, a person can much more easily reproduce that recipe again on other systems or at large scales.

Summary

This all results is more repeatable beers and accurate numbers than other brewing tools I’ve tried which is why I continue to use and update my spreadsheet rather than use another program.

I hope that helps. Now go forth and brew!

Hey Larry, I saw your live stream video today with you and Chad which I enjoyed, I asked you a question if using your spreadsheet would help me brewing hoppy beers, Im just having a hard time having aromatic beers. I use Brun water and still not good enough as I expect. I just wonder what others do. I am always brewing IPAs and my beers are not hop bombs as I hope they were and by the way I get all my hops from Yakima valley, I buy in bulk since I get a better deal. Can you help me with this?

For hoppy, I assume you mean hop flavor and aroma. Late hop additions, hop stands, and dry hopping all contribute to those. Some water chemistry can help accentuate the flavor too. For example, higher levels of calcium can help out pale ale and IPAs.